-

SEARCH

Type your search in the field above

Improving our handling and sorting of waste is a continuous priority for LSG. Increasing our sorting grade of waste for reuse and material will greatly impact our environment through reduction of unwanted, hazardous and non-biodegradable waste in the environment .

In late 2022 LSG signed a corporate agreement with one waste handling company to handle all waste from our operations in Norway. This will significantly increase our waste handling Management opportunities and secure that our waste is treated in the most sustainable manner possible. The agreement will also ensure that the data quality of reported waste and treatment method is better. An automated transfer of data to our Environmental accounting system (Cemasys) is in place which will also result in a decrease in manual labour connected to reporting.

Throughout the year we communicate through different forums with our stakeholders to discuss our immediate -and potential impacts regarding waste. It is important that we get input from our stakeholders on what they find important and are concerned about so that we can improve our waste handling and implement best practices. Our waste handling company in Norway are for example involved in, and have give input on how we have formulated our KPI on recycling.

Using one strategic partner for all our waste handling in Norway will significantly influence how the local and central management works with waste. It will also give us the opportunity to better influence how -and what happens with our waste fractions. We see several opportunities in the future to strengthen our engagement and commitment to increase our degree of recirculation within the group, also outside of Norway. We are looking at the possibility to expand this strategic agreement to also include Scandinavian countries where we have operations.

In 2024 the corporate agreement with one waste handling company in Norway has:

1) resulted in better reporting functionality

3) resulted in an infrastructure to handle and maintain service for all our locations in Norway

4) resulted in a clear strategy for recycling

5) Resulted in increased knowledge and knowhow regarding waste sorting and treatment

6) Given us new ways to communicate with stakeholder and other third party organizations through the waste handling company.

During 2023 a new EU directive on waste handling was applicable for our operations. New targets for diverting waste from disposal is included in the directive. Our new agreemet with one waste handling company will help us reach these targets .

Using one supplier will also put us in a position to better influence that our waste is not unnecessarily sent for disposal which can impact the environment negatively. This is however more difficult in our downstream operations where each company still uses local suppliers. This results among other things in volumes of waste being diverted from recycling to landfill or Incineration (energy recovery). We are working with our suppliers downstream in Europe to better understand how we can increase our share of waste being diverted to recycling.

In collaboration with our waste handling companies (both in Norway and Europe) we have implemented sorting regimes in all our locations and strive to make sure that all our waste is handled in a sustainable way by us and the recipient of the waste. In this the different waste handling companies, local and National governments are the main contributor and drivers to make the big changes. Without involvement, dedication and investments from them, it is difficult to see a significant change in share of waste being diverted to recycling.

We are committed to continue our work with different stakholders and the UN Global Compact initiative to do what we can to push for change within the national and global regulations for waste handling and sorting. Our companies will also continue to audit and followup our suppliers on waste handling to make sure that our waste is handled in a legal and sustainable manner.

All waste fraction data is mandatory to report to the group through its environmental reporting system (Cemasys). Data reported monthly is based on invoice from Waste handling companies.

Lerøy have not received any whistleblowing cases regarding waste management, waste handling or any misconduct regarding waste in 2024. We have neither received any fines, lawsuits or other legal actions towards us in connections to our waste handling and management.

Safety for our workers are always high on our priority list. Making sure that no one gets injured or sick handling waste in our, or our suppliers workspace is essential and governs our operations. Strict HSE procedures and guidelines are in place to ensure that our workers health and safety is secured. All employees who have training and are approved for handling hazardous waste is provided with required protective equipment.

For more information regarding our waste managment please see our Policy on waste management

The group increased its share of inorganic waste which was recycled (Material recovered and re-used) in 2024 with 0,8 % compared to 2023. Our share of recycled waste was 44,33 % (4 051 294 kg) of total volume inorganic waste, compared to 43,54 % (3 737 273) in 2023. The total volume of inorganic waste in the group have increased from 8 039 620 kg in 2023 to 9 138 866 kg in 2024.

The recycling of inorganic waste is for now stable at about 44-45 % of the total volume. We aim however to increase this share to 50 % in 2025 and 65% within 2030. Cooperation, and finding sustainable sulutions together with our waste handling companies will be priority, in combination with optimizing our sorting at our locations. We see that we still have improvement possibilities to effectivly sort and clean waste before disposal. The main reason for this is available space at farming locations to both sort and store waste before pickup. We are looking at different solutions together with our supplier, and hope to increase our degree of sorting going forward.

In our downstream operations in Europe we still have local suppliers for waste handling per company. During 2024 our data quality have improved and several companies have taken appropriate steps to increase their collaboration with these suppliers, resulting in increased our focus on training, knowledge sharing and supplier followup. Actions taken to increase data quality:

We are confident that our share of recycled inorganic waste will increase in 2024 as a result of our strategic partnership with one supplier of waste in Norway, and our actions taken in our Downstream operations.

Waste presented in tables below are reported from our production operations throughout the group. We also have small volumes of waste generated from our offices.

Table 1: Overview of inorganicwaste volumes in Tons per treatment type, % of total waste and % change compared to last year (2023) in LSG.

|

Treatment type |

Volume in tons |

% of total waste |

% Change (last year) |

|

Recycled |

4 051 |

44,33 |

0,8 |

|

Energy recovery |

4 726 |

52 |

14,2 |

|

Landfill/ Composting |

360 |

3,9 |

-12,1 |

The overall result of 2024 shows that we had an increase of 0,8 % in volume of inorganic waste beeing recycled compared to last year. The 12,1 % decrease in waste beeing directed to landfill is connected to an increase of investments in rehabilitation of existing buildings in Norway 2023. This generated waste which only can be put on landfills.

Our goal for 2024 is to increase the non-organic waste which is recycled (material recovered) to 50 % in 2025, and 65% in 2030

Our target to increase the share of inorganic waste which is material recoverd is ambitious. We feel however confident that it is possible to reach the target in partnership with our waste handling company. In accordance with the EU Waste Directive the target for 2030 is 65 %.

The share of hazardous inorganic waste in LSG has increased from 75 498 kg in 2023 to 696 217 kg in 2024. The increase is mainly related to old farming nets beeing discarded. Some of our factories still use fluorescent lights, so by changing them to LED lights we can reduce this even further. In addition, the electrifying of our feeding stations will also reduce our hazardous waste by eliminating the use of oils and lubricants for our generators. Lerøy did not have any hazardous organic waste in 2024.

Table 2: Waste by composition, in metric tons. Organic waste included.

|

Waste Generated |

Waste diverted from Disposal |

Waste directed to disposal |

|

|

Non Hazardous Waste |

69 553 |

65 074 |

4 479 |

|

Hazardous Waste |

696 |

88 |

608 |

|

Total Waste |

70 250 |

65 163 |

5 087 |

Table 3: Non Hazardous Waste diverted from disposal by recovery operation, in metric tons. Organic waste included

|

Onsite |

Offsite |

Total |

||

|

Non Hazardous waste |

Preparation for reuse |

0 |

0 |

0 |

|

Recycling |

0 |

65 163 |

65 163 |

|

|

Other recovery operations |

0 |

0 |

0 | |

|

Waste prevented |

|

|

|

65 163 |

Table 4: Hazardous Waste diverted from disposal by recovery operation, in metric tons. Organic waste included

|

Onsite |

Offsite |

Total |

||

|

Hazardous waste |

Preparation for reuse |

0 |

0 |

0 |

|

Recycling |

0 |

88 |

88 |

|

|

Other recovery operations |

0 |

0 |

0,0 |

|

|

Waste prevented |

88 |

Table 5: Hazardous Waste directed to disposal by disposal method, in metric tons. Organic waste included

|

Onsite |

Offsite |

Total |

||

|

Hazardous waste |

Incineration (with energy recovery) |

0 |

606 |

606 |

|

Incineration (without energy recovery) |

0 |

0,0 |

0,0 |

|

|

Landfilling |

0 |

1,5 |

1,5 |

|

|

Other disposal operations |

0 |

0 |

0 |

Table 6: Non Hazardous Waste directed to disposal by disposal method, in metric tons. Organic waste included.

|

Onsite |

Offsite |

Total |

||

|

Non Hazardous waste |

Incineration (with energy recovery) |

4 120 |

4 120 |

|

|

Incineration (without energy recovery) |

0 |

0,0 |

0,0 |

|

|

Landfilling |

0 |

359 |

359 |

|

|

Other disposal operations |

0 |

0 |

0 |

LSG did not store any waste onsite longterm during 2024. Some Hazardous wastes of small quantities are stored safely and within regulations in storage lockers design for the purpose. Waste handling company handles and transport in accordance with relevant regulations.

Lerøy Havfish AS participated in Fishing for Litter also in 2024. Fishing for Litter is an initiative to clean our oceans for old fishingequipment and other wastes. In 2024 Lerøy Havfisk collected 210 tons of waste during their fishing trips.

ORGANIC NON-EDIBLE MATERIALS

Organic waste in the group is reported in accordance with (EU) nr 142/2011.

Table 1: Overview Volume (Tons) and % change last year in Category 2 (Farming), 3 (Industry and VAPS&D) and Organic sludge.

| 2022 | 2023 | 2024 | % change last year | |

| Category 2 | 24 739 | 26 432 | 17 714 | - 33 |

| Category 3 | 48 740 | 43 282 | 38 774 | - 10 |

| Organic sludge | 4 904 | 8 479 | 4 623 | - 45 |

Tabell 2: Overview in % per category 2, 3 and Organic sludge of total production volum in Farming (Category 2) and Industry and VAPS&D (Category 3).

| 2022 | 2023 | 2024 | % change last year | |

| Category 2 | 7,9 | 12,8 | 5,3 | - 7,5 |

| Category 3 | 14,3 | 15,7 | 22,5 | 6,8 |

| Organic sludge | 0,74 | 3,7 | 1,4 | - 2,3 |

An important part of Lerøys strategy is to reduce mortality in our farming operations, reducing at the same time the food waste we generate. Biological factors and external influence on fishhealth and welfare are important contributors to mortality in some regions. In 2024 our Category 2 organic waste was reduced from 12,8 % (2023) to 5,3 % (2024). Lerøy have implemented several measures to reduce mortality in 2024. The most important are:

- We have invested in a harvest boat which will significantly increase fish welfare and volumes for harvest from our farming operations.

- We have developed and implemented semi-submergeable farming cages and semiclosed cages, reducing external factors influence on fish health and welfare

- Increased and strengthened our vaccine programs.

- Increased focus on broodstock genetics.

The increase in Category 3 organic waste is related to increased production volumes 2024.

Lerøy also have several initiativs ongoing to better utilize the potensial in our sludge generated. Sludge from our farming and Industry are utilized both for biogas production and earth improvement (compost in agriculture).

RECYCLING

Recycling all waste types where we can is important. Together with our waste handling companies we strive to increase the share of waste which is re-used or material recovered and have set a target of 65 % material recovery within 2030. Together we have initatives to find the best solutions for upcycling and downcycling our waste fractions. We are working closely with our suppliers and waste handling companies to find sustainable solutions, and materials which are recyclable. In our farming operations we use some types of ropes which cannot be material recovered because they are not made from the right materials. Dialogue with suppliers to find good sustainable solutions or replacements are ongoing.

The Group is actively involved in the process of recovering plastic waste from the oceans through different programs, in order to protect marine wildlife. One of the activities is recycling our fish farming nets, ropes and old trawlernets.

Another activity is: “ Only on loan”. This is a project in which Lerøy Seafood works together with waste and recycling company Norsk Gjenvinning to ensure that the packaging for products packed in aluminium trays is returned for recycling after use. Such packaging materials is therefore only “on loan”.

Waste is a resource that is not properly utilised, and we aim to do something about it. We also focus on using the correct packaging and the correct size of products in order to avoid waste.

USE OF ORGANIC SLUDGE FROM SMOLT PRODUCTION

Since 2013, when the juvenile production facility Belsvik opened, we have sent our organic sludge to a biogas production facility. The use of Organic sludge as biogas is sustainable, but we have found that long transportation of sludge with high content of water was less sustainable. We do not release an sludge to public waterways.

Investment in a drying facility on location was therefore recently decided and from 2023 we will be able to deliver dried sludge to the agriculture industry.

The Sludge will be used as a soil improvement material and fertilizer. Our other two major smolt production sites in Laksefjord and Kjærelva is already drying their sludge on site for the agriculture industry.

SUGAR KELP

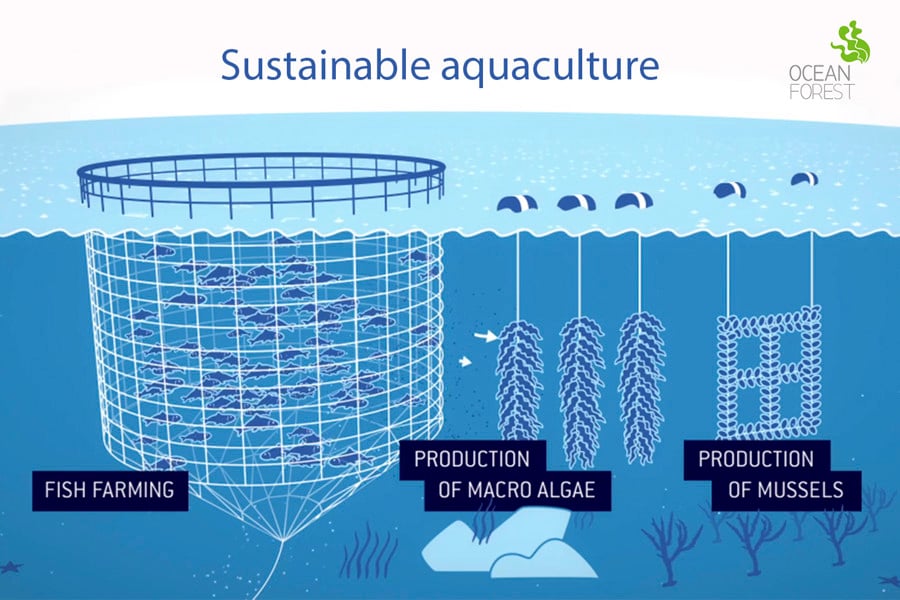

Lerøy produce Sugar kelp and Blue mussels in areas where we have farming activities. The macroalgea absorb excess nutrients from the sea, requiring no freshwater, feed or fertilizers and absorb Nitrogen, phosphor and CO2. The combination of fishfarming and macroalgea production in the same area is a perfect way to recycle excess nutrients and at the same way reduce our Carbon footprint.