-

SEARCH

Type your search in the field above

The UN Food and Agriculture Organization (FAO) has estimated that the world's population will increase to approx. 9.1 billion people by the year 2050.

According to the FAO, a population growth of approximately 30% by 2050 will require food production to increase by about 70% to meet the demand. Regarding seafood, the FAO has projected that the demand for seafood will increase by about 40 million tons by 2030.

Approximately 71% of the Earth's surface is covered by oceans, while the remaining 29% is land.

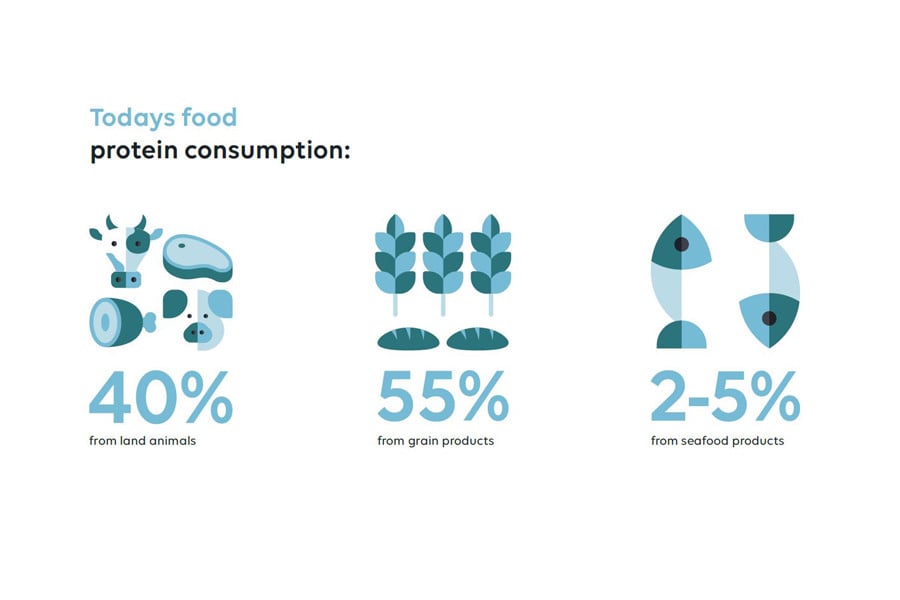

Seafood actually accounts for about 20% of the animal protein consumed worldwide.this includes both wild-caught and farmed fish, and it's a significant source of nutrition for many people globally.

Farmed seafood is highly sustainable from a climate perspective for several reasons:

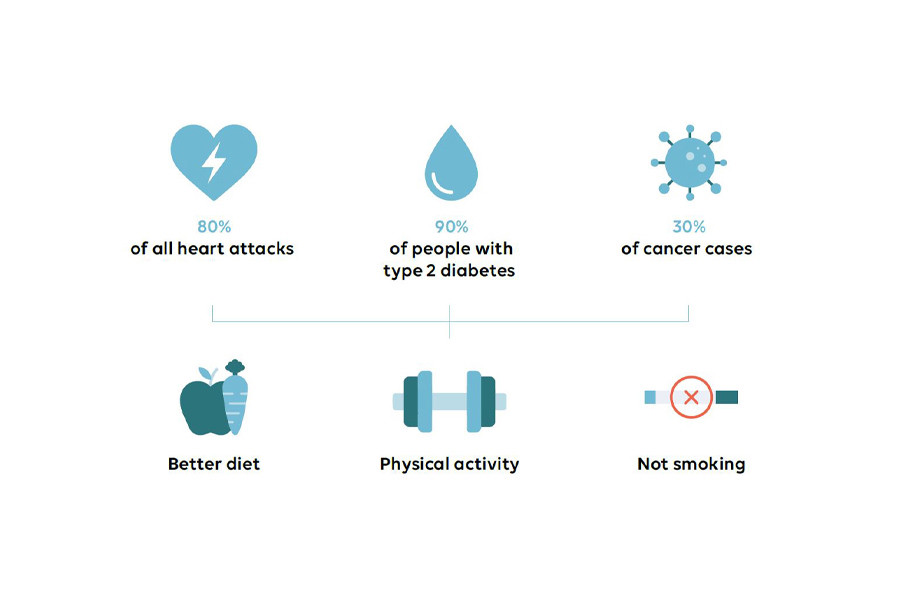

Unhealthy diet can cause various types of illnesses. Poor diets are linked to numerous health issues, including cardiovascular diseases, diabetes, and certain cancers. Lifestyle diseases can be prevented by ensuring a correct diet. Many non-communicable diseases (NCDs) can be prevented through healthy eating habits. Dietary experts recommend eating more seafood and less red meat. Many health experts advocate for increased consumption of seafood due to its beneficial nutrients and lower environmental impact compared to red meat. Promoting seafood consumption can contribute to better health outcomes and sustainability.

SEAFOOD IS GOOD FOR YOU!

Fatty fish like salmon, mackerel, and sardines are high in Omega-3 fatty acids and generally have lower Omega-6 content. While Omega-3 is often emphasized for its health benefits, it's important to maintain a balanced intake of Omega-6 as well.The World Health Organization (WHO) emphasizes the importance of a balanced ratio of Omega-3 to Omega-6. Seafood is rich in vitamins A, E, and D, and minerals like zinc and iodine. Cod, in particular, is a good source of iodine. Many health authorities recommend increasing fish consumption and reducing red meat intake for better health outcomes. Salmon is known to have positive effects on cardiovascular health and may help prevent other conditions like dementia and diabetes.

Within the Group, we place a strong emphasis on health – the health of our employees, as well as our current and future consumers. Each individual, the consumer, is vital both to the community and to us in the Group, as they are the ones who purchase our products and thereby secure our jobs.

Lerøy Seafood Group is a partner in the Agreement of Intentions for a Healthier Diet, together with the Norwegian Directorate of Health. This letter of intent aims to foster a more holistic, coordinated, and targeted cooperation between the food industry and health authorities, making it easier for consumers to make healthier choices. The goal is to increase the proportion of the population that maintains a balanced diet in line with the authorities' dietary recommendations.

As a result of the Group's feed strategy, which includes using alternative resources in feed and purifying marine fish oil to remove undesirable substances, we have reduced the levels of contaminants such as dioxins and DL-PCBs in salmon by 42%, from 0.662 pg/g in 2011 to 0.385 pg/g in 2024. The Tolerable Weekly Intake (TWI) estimates the amount per unit body weight of a potentially harmful substance or contaminant in food or water that can be ingested over a lifetime without risk of adverse health effects. The TWI for dioxins and DL-PCBs is 2 pg/kg body weight.

Another contaminant that has received significant attention in recent years is PFAS. This group of chemicals is classified as carcinogenic and has several adverse effects on humans. The most common source of PFAS exposure is through food and drink. Analyses from 2023 show that salmon farmed by Lerøy has very low levels of the most common forms of PFAS. With analyzed values of 0.01 µg/kg PFAS in salmon, an adult (75 kg) could consume up to 33 kg of salmon per week before exceeding the Tolerable Weekly Intake (TWI) set by EFSA.

Lerøy farmed salmon consistently contains high levels of EPA/DHA, with analyses showing an average level of 1.18 g/100 g in 2024. This means that by consuming a portion (200 g) of Lerøy salmon, you can meet your Reference Weekly Intake (RWI) for EPA and DHA. The RWI for combined EPA and DHA is 1.75-3.5 g. Salmon constitutes approximately 50% of the total seafood production within the Group.

Read more about the choices Lerøy has made regarding salmon here

SALT

In 2016 the Group made an agreement with Norwegian health authorities. The agreement obliges the parties to work towards reduction of salt.

Salt intake in Norway will be reduced by 30% by 2025.

The salt partnership - "Saltpartnerskapet"

The goal of the salt partnership is to stimulate the food and catering industry to reduce the content of salt in foods and food served, as well as to increase awareness of salt and health in the population. Furthermore, dissemination of knowledge and competence, research, information to consumers and monitoring of the efforts are key tasks.

Key facts and figures

More than 3.1 billion people rely on fish for at least 20% of their total animal protein intake, and an additional 1.3 billion people depend on fish for 15% of their animal protein intake.

Often discarded parts of the fish, such as the head, viscera, and backbone, make up 30-70% of the fish and are especially high in micronutrients.

Fish consumption has indeed increased from about 9 kg per capita in 1961 to over 20 kg per capita today.

Food safety refers to the measures taken to ensure that food is safe for consumption by humans. Ensuring food safety is critical for protecting the health and wellbeing of people and the sustainability of the food industry.

Lerøy survey all products for contaminants and microbiological levels throughout the value chain, in addition to obtaining a robust food safety culture. This to ensure that all our products are safe to consume for the population. Exceeding limits or breakage of food safety measures and produce contaminated food can create harmful effects to vulnerable populations, such as children and the elderly. In addition, it may cause food loss.

To be able to handle a breach with food safety, Lerøy has defined clear recall measures to be able to trace and stop a product within 4 hours. An insufficient recall can result in significant financial losses. Unsafe food may lead to foodborne illnesses, which can cause a range of symptoms from mild discomfort to severe illness.

Ensuring food safety increases consumer confidence in Lerøy’s products, which can lead to increased sales and revenue.

The Group’s strategy is to meet or exceed the market’s requirement for food safety, quality, product range, cost efficiency and continuity of supply. This is achieved by coordinating the various elements in the value chain: the production units, the Group’s sales network, and established strategic alliances with sea farms, fishing vessels and fish-processing plants, primarily along the coast of Norway.

The Group is actively involved in all parts of the value chain to ensure supply of safe products to the consumer. Based on experience gained over many years, we have developed a quality system comprising routines and procedures to ensure supply of safe products.

As a part of the Group`s quality assurance routines, we carry out control and monitoring of our manufacturers and partners. This involves specifying requirements for their quality systems and routines, and carrying out analyses, audits and monitoring operations.

All products are controlled by Lerøy Seafood Group at different stages throughout the entire production process; from roe, boat and purchasing station to the finished and boxed product and, in certain cases, up to delivery to the customer.

For many years, the Group has followed a definitive strategy for quality assurance. Our strategy is that 100% of our facilities processing products must obtain a GFSI recognized food safety standard (BRCGS, FSSC 22000 or IFS).

100% of Lerøy owned factories supplying whole salmon and trout have a GFSI certification (BRCGS or FSSC 22000).

For purchased raw material and ingredients 50% of our suppliers have a GFSI certification, which entails that 63% of purchased products is supplied by a certified producer.

Food safety reporting system

In the last years the Group has invested in a live food safety microbiological reporting system. The system receives microbiological result directly form the laboratory, we receive results of microbiological test more quickly, and can implement more efficient food safety actions if nonconformances should occur.

The programme imports microbiological results from product samples, cleaning samples and environmental samples directly from the laboratory as soon as the results are ready. The processing facility receives the results immediately and the results are then visualized in the system automatically. We also have the possibility to get immediate warnings if results are out of set limits. The microbiological results on equipment, direct & indirect surfaces and products are imported and visualised in a chart, making it easy to analyse trends and see where and when detections occur and take preventive action.

The system has enabled us to act on non-conformities early ensuring food safety on end products. One example is to block a fillet machine if Listeria monocytogenes is detected on the environmental surfaces before Listeria contaminate products.

In 2020 Lerøy initiated a new way to measure food safety culture across the companies in the group, a new survey was carried out in 2024.

Food safety culture is defined as the food safety attitudes, beliefs, behaviour and values shared by all the employees in the company. The food safety robustness is essential in a company that produce safe and sustainable quality seafood.

Measurement of Food safety culture is combined with the yearly employee survey GPTW that Lerøy assess every year. The result of the survey identifies improvement areas for the food safety culture in each company and give the possibility to measure it against a benchmark for the Food safety culture in the group or within a specific segment each year. Each company put down an action plan how to improve or maintain a high food safety culture.

Full traceability throughout the entire value chain is essential for food safety. If there is a fault in a product without traceability, we may not be able to identify the cause of the nonconformance, take action or be able to trace where the product has been sold for efficient recall from the market. If a situation occurs when people get sick because of a product and we cannot trace it efficiently, this represents a direct risk for food safety. Today's consumers are conscious; and want to know a product's origins and how it has been handled. This requirement would be impossible to meet without a well-developed traceability system.

Lerøy shall be the foremost seafood company in terms of tracking and extended tracking technology.

Lerøy have full traceability for all seafood products, input factors for products and raw materials for salmon and trout feed.

Lerøy’s in-house developed tracking system, Fishtrack, provides all customers with access to online tracking information for a product, all the way from parent fish to processing. In essence, the customer has a CV for the fish they have purchased, including information on broodstock fish, juvenile fish, sea farm location, feed, treatments, quality analyses etc. We achieve this by linking the Farming segment’s traceability system with the ERP system used by our Sales Department. One unique code follows the fish throughout the value chain, with related traceability information.

Lerøy can now track and block any product on the market within 4 hours, along with associated raw material batches and batches of finished goods.

For whitefish and wild catches, information on fishing sub area, fishing gear, catch date, landing date, production date and processing facility is available.

The Group have launched a product traceability system on the customers Blockchain solution (i.e IBM). Products with a full traceability, consumer facing QR code are now available for consumers in shops. The Group is working on a similar solution for whitefish products.

The Group carries out traceability tests/recall drills every year to ensure that our system is efficient and robust. 100% of the processing facilities must perform a drill each year.

In 2024, 22 traceability/recall tests were carried out. No serious nonconformances where detected

You can read more about the recall test here

|

|

Target |

2024 |

2023 |

2022 |

2021 |

2020 |

|

Traceability tests conducted for production facilities |

100% |

100% |

100% |

100% |

100% |

100% |

Lerøy was one of the first companies to establish a traceability portal with direct access for consumers in Norway, with the “gladlaks” concept. Consumers can use a code on the packaging to gain full traceability information specific to the salmon they have bought, and more detailed information on the concept and on Lerøy’s fish farming methods.

We have now made further developments to the concept and can offer traceability information to BlockChain systems for several European customers. Products have now been launched on the market with a QR code providing consumers with full traceability information on the product, where it was farmed and processed along with related information.

The customers have access to a map where they can see the location of the juvenile fish facility, the farming location or the slaughter facility where the product has been farmed or processed. This boosts confidence in the product and in all parts of the value chain.

Lerøy is constantly seeking opportunities within tracking technology to remain the foremost seafood producer in terms of traceability. Lerøy can offer a comprehensive seafood tracking portal for our customers.

Lerøy is also participating in the EU project, development of a product environment footprint pilot (PEFCR) to be able to calculate an correct environment footprint for each of our product combined with our traceability solutions.

Traceability is an essential requirement to be able to recall products that are not safe to eat or have non-conformities that affect the product’s properties. Rapid product recall and sharing information are crucial if we are to prevent or minimise an outbreak of illness caused by a product.

A recall is when a product with defects that violate food safety, have reached the end consumer and is removed from the marked. A withdrawal is product with the same characteristic but are removed in the supply chain before it has reached the consumer.

The Group’s ambitions is to take preventive action and have zero Lerøy product recalls.

Lerøy has established product recall procedures that specify in detail what to do if a non-conformity is detected in a product once it has left the company. Product recalls are defined according to the type of non-conformity and the risk category. Lerøy has also established both central and local emergency preparedness groups to manage product withdrawals. This allows us to develop the routines and competencies required for efficient product withdrawals.

The Group conducts preparedness/recall tests every year to make sure that the procedures work properly.

The preparedness group for the Group consists of:

The core & responsible of the preparedness group comprises of the CEO and Head of ESG & Quality. The other members are invited to meetings depending on the items to be discussed – Farming, VAP/ Sales, Fisheries or processing. The preparedness group has primary responsibility, both internally and externally, for communications and handling of any relevant challenges/crises.

Preparedness plans are also drawn up locally. All facilities have a local preparedness group if a recall should be necessary. The preparedness group consists of persons representing all parts of the operations.

The typical procedure for product recall consists of the following phases:

All product recalls and withdrawals are recorded in the company’s quality system, LQMS, by all Group companies, and statistics are monitored centrally. If any recall occur an action plan finding the root cause and actions to eliminate it must be described and followed up in the system.

We have a target of 0 recalls since this has the highest impact on the market, no target has been set for the number of withdrawals as these are products that have not reached the market and are proof that our tracking routines and control work.

Lerøy will always perform recalls if our product does not meet our foodsafety requirements, either as a precautionary or an corrective action.

Lerøy has not identified any non-concompliance with regulations and/or voluntary codes in 2024.

Every year the Group performs a traceability / recall tests to verify that the traceability and recall system works correctly and efficiently, our recall procedure can be initiated and operated at any time and required finalized within 4 hours. It is essential to train employees and improve recall procedures to be able to ensure an efficient recall regarding food safety if a real case should occur.

A traceability test/recall test is a fictive case related to food safety, which includes: Processing facility, harvest facility, farming including juvenile stations, feed supplier, sub suppliers, the authority and customers. All actors must supply correct documented information. It is also checked if relevant key contact/ out of hours contact details are up to date and correct.

After a recall test, a summary is compiled by the preparedness group and improvement points are identified and implemented. A recall has a time limit of maximum 4 hours.

The Quality Manager at the production facility (QMP) together with the quality Manager at the sales department (QMS) are responsible to ensure that all recalls are carried out according to the recall procedure. QMP and QMS are also responsible involving correct personnel, external expertise and recover documentation required (analytical reports, quality assurance log, traceability information etc).

In 2023, 3 batches of Lerøy products were recalled from the marked.

Two of the recalls was due to detection of listeria and one recall was due to error in labelling. A total of 568kg were recalled.

In all recalls corrective action with root cause were carried out to prevent recurrence.

|

|

Target |

2024 |

2023 |

2022 |

2021 |

2020 |

|

Product recalls (number) |

0 |

7 |

3 |

11 |

5 |

0 |

Production of Atlantic salmon and Rainbow trout is considered more sustainable compared to production of beef, pork, sheep and other land animal-based proteins. The reason is that land animal-based proteins are more discharge intensive because of the methane gas they produce.

To reduce our overall emissions and trap excess nutrients such as Nitrogen, phosphor and carbon from our salmon and trout production, Lerøy in partnership with NGO Bellona Holding AS, started a joint venture, Ocean Forest, to produce macro algae, blue mussels and polychaeta near several of our farming sites.

In addition to trap CO2 and absorb excess nutrients from the farming operations, especially the blue mussels, but also the sugar kelp are good sources of sustainable proteins and other health benefitting nutrients.

Ocean Forest has conducted two studies of fermented kelp in feed for ruminants in collaboration with the University of Copenhagen. The first study is an in vitro study, in which the methane gas production in the stomach of dairy cows is added to various fermented kelp products. The measurements showed up to a 45% reduction in methane gas production using fermented kelp.

The second experiment was performed on calves. The calves could choose freely between 4 different diets with 0 to 5% fermented kelp added. The feed with the highest content of fermented kelp was clearly most sought after by the animals.

The studies in Denmark have shown that fermented kelp can be an important new ingredient in feed to land animals to reduce their emissions of methane gas by 30-40 % (Hansen et al, In prep) when adding Sugar kelp to their diet. Ocean Forest sold most of the production of sugar kelp in 2021 as a new ingredient for animal feed.

Using blue mussel meal instead of fish meal has also shown to be an excellent replacement as shown in the EU funded project Holofood. We therefore started an inhouse R&D project with one of the major Feed companies to see if blue mussel meal is viable commercially.

We also include 1,5 – 2 % insect flour in all our freshwater feed as a replacement for fish meal. From a nutritional point of view, it is considered a high quality and sustainable protein source, but its highly expensive to use.

The growth potential of this business venture is far greater than what we produce today, and what we will be able to produce in a long while. Today we have blue mussel and sugar kelp production at 7 locations (5 sugar kelp locations and 2 blue mussel locations). We produced 230 tons of sugar kelp (2,3 tons protein) in 2022 and estimate a significant increase in production volume in 2023. We also produced 3 tons of Blue Mussel protein.

Our goal is to one day have the knowledge, technology, and the customer base to extend this production setup to a major part of our farming sites, producing more sustainable marine and plant proteins.

We are also committed to continue educating the public about the benefits of a diet consisting of marine proteins, Omega 3 and 6 fatty acids and other health benefiting nutrients. Doing so, we are confident that the human consumption of these sustainable proteins will increase in the future.

In 2021 Lerøy started a R&D project lead by our product development team to look into the possibility to diversify our protein assortment, expanding into plant-based protein products. Our goal with the project was to find a partner which could help us find suitable replacements for fish proteins in an assortment of “fish like products” such as Vegan Maki with salmon and shrimp, Vegan Salmon burger, Key west Crab cake and more.

Consumer interest in plant-based fish alternatives is growing and is poised for a rapid rise like other alternative protein products. It is being driven by the same macro trends but playing out in ways specifically related to the fish and shellfish industry. The Vegan market is expanding along with the growing demand for sustainable food, and Lerøy plans to be a part of this trend offering a wide arrangement of product to satisfy our customers need for fish products, and plant based fish alternative products in the future.

The project is still ongoing in 2024 and therefore not ready for publication. Our trails and tests with our partner in 2024 did not produce the results we expected regarding texture, taste, and appearance. We started therefor to test other possible sources of raw materials and recipes within the vegetable assortment. The development and testing will continue in 2025. The main goal is to develop, produce and launch in the market a vegan burger based on vegetable protein using different types of vegetable puree, dried sugar kelp, natural aromas, starch and more. In addition, we are developing other different product ranges utilizing vegetable raw materials, and sugar kelp from our own production in Ocean Harvest. Sugar kelp pesto and sugar kelp salads are some of the products in this range which is being tested internally and with external testing panels.

The largest challenge we face at this point is to find a plant-based protein which can simulate the Atlantic salmon texture giving the right resistance in the mouth, creamy sensation on the tongue or the elastic bite when chewing.

In addition, appearance and taste need to be perfect before products from this range will be ready for market. We continue this project also in 2025 and have ambitions to have plant-based protein products ready for market during 2026.

The Group focuses on packaging and is constantly searching for good, sustainable packaging solutions.

Lerøy is committed to work towards a sustainable packaging material portfolio within 2030 for all products. This entails using packaging materials that reduce food waste, prolong shelf life and product quality in addition to having the lowest possible eco footprint.

To achieve our goal we are reliant on working together with our customers, our suppliers and regulatory bodies to transition from the use of non-recyclable/biodegradable packaging materials, to materials which can either be recycled, reused or is bio degradable. In addition we need to help ensure that the infrastructure for recycling/reuse is sufficient to handle the quantity used.

There are several reasons why good sustainable packaging solutions are important for Lerøy and our customers. First of all our products needs to reach its destination safely without compromising the products food safety and product quality. Secondly we need to ensure that we do this as economically as possibly so that we can offer our products at a competitive price. This means that the packaging not only needs to be priced correctly, but it also needs to be within our specifications when it comes to weight, durability, recyclability and composition. Thirdly the packaging material needs to fit into our sustainability strategy and fulfilling all regulations and industry standards. We need to make sure that our choices is sustainable and at the same time not compromising food safety.

To ensure that all companies in the group work towards the same objectives we have established a category team for packaging. The team work closely with not only our own companies and suppliers/producers, but also other aquaculture companies and NGO`s to make sure that the best packaging solutions are always used. The team is comprised of people from different departments in Lerøy with different knowledge and experience to ensure that we make the right decisions for our customers, and the environment.

Lerøy have set a target to reduce the use of plastic in the Group by 50 % within 5 years (Base year 2019).

Packaging materials is one of the categories we have targeted to be a contributor to reaching this target. To be able to reach this target we have had to challenge all our suppliers of materials containing plastic. In the past 2 years we have had several workshops and meeting with suppliers to find alternative packaging materials, reducing the volume of plastic used, and discussions regarding different R&D projects.

We work continuously to use as least packaging as possible without compromising on food safety.

The Group is looking into the possibility to use packaging made of organic materials from the sea. The hope is to wrap the seafood in organic material from the sea which is biodegradable.