Production of sugar kelp

Producing sugar kelp is a very efficient way of binding CO2 already dissolved in the sea. Farming sugar kelp does not require any input of freshwater, fertiliser, pesticides or land. The plant captures the nitrogen, phosphorus and carbon (as CO2) directly from the ocean. On average, 1.000 kg (wet weight) sugar kelp contains 26 kg carbon equal to 100 kg CO2 – which is higher than the same volume for wood.

Ocean Forest AS is an R&D company, and the Group has a 50% share in this company together with NGO Bellona Holding AS. The company is focusing on the production of low trophic species such as macro algae, blue mussels and polychaeta.

Main goal:

Utilise sugarkelp as an feed ingredient for cattles, giving an substantial reduction in emissions from cattle farming.

Production of blue mussel meal

Ocean Forest AS also focuses on the production of blue mussels, not for human consumption but mainly as a source of marine protein. We have conducted a series of growth studies with Atlantic salmon demonstrating that blue mussel is an excellent fishmeal replacement.

The challenge has been to produce a blue mussel meal free of shell fractions on an industrial scale. We have now ordered special equipment that will enable us to separate the meat from the shell on an industrially efficient scale. Testing and implementation of the equipment will take place in 2020. Blue mussels will also contribute to cuts in CO2 emissions.

More efficient feed control

The Group has a constant focus on the footprint from our fish farming activities. Faeces and uneaten feed on the seabed beneath our cages can represent a local undesired impact on the environment. This issue is addressed with an increased focus on feed control but also how to optimize the raw material used and the amount and physical quality of the faeces.

Ocean Forest focuses on the organic matter that reaches the seabed and how we can increase the turnover of this material. Our focus is on polychaeta; how to support the establishment of an active and heathy community of this species and how to harvest the surplus for use in e.g. fish feed for other species than salmon.

In collaboration with the Institute of Marine Research in Norway and the University of Wageningen, we have in recent years conducted a series of studies indicating the turnover rate and species present. We have developed a “polychaeta vacuum cleaner” for harvesting and one of our employees is now studying in detail these challenges in a PhD programme with the Institute of Marine Research/University of Bergen.

New raw material for feed

The Group has a major ongoing programme for developing new innovative raw material for fish feed. Historically, Lerøy has been a prime mover regarding the use of Omega-3 fatty acids produced from microalgae to increase the level of Omega-3 in our feed compared to industry standard, and for the introduction of Camelina oil and the ban on ethoxyquin. Last year, we were the first company to start using insect meal in all our freshwater feed delivered by one of our feed suppliers.

Today, we buy the full volume of insect meal the producer can produce. We are also involved in very interesting projects relating to blue mussel meal and seaweed in salmon feed. Both projects are part of a major EU-supported project – “Holofood”, involving a series of issues, such as feed utilisation and retention, growth performance, fish and gut health.

Methane reduction with sugar kelp

The Group is also delivering sugar kelp to an exciting project in Denmark. In the project, they mix sugar kelp with feed for cows. Compared with ordinary diets with normal cow feed, the project shows that this mixture provides a 50% reduction in the methane emissions from the cows. Fermented sugar kelp in feed also proved successful.

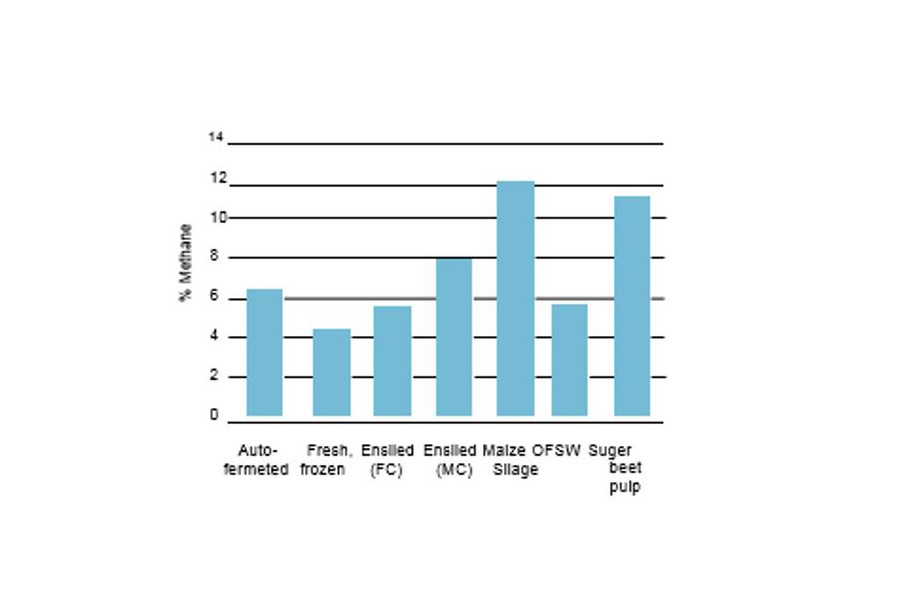

Methane concentration from pure sugar kelp feed, maize silage and sugar beet pulp fermented.

While the use of antibiotics is almost non-existent in Norwegian fish farming, it is a major problem in production of red meat. Here too, sugar kelp can be helpful. The trials in Denmark show that sugar kelp in pig feed, helps with intestinal health and reduces the need for antibiotics.

Project 50/50-5 Food waste

Globally food waste contribute to 8-10 % of greenhouse gas emissions. By reducing food waste we also reduce our climate foot print. About 2 kg of CO2e are emitted for 1 kg of food waste.

Food waste includes all usable parts of food produced for humans, but which are either discarded or removed from the food chain for purposes other than human food.

In project 50/50-5, the Group has chosen to include reduced mortality in farming and utilisation of residual raw materials from wild catches to produce fishmeal, fish oil or silage. Such raw materials are used for human consumption or animal feed, generating food for humans.

The Group has participated in a SINTEF project to map the amount of food waste that occurs in the seafood industry, enabling sub-projects to be set up that have an impact.

We aim to increase the edible proportion of today's food waste by 50%, including reduction in mortality in farming and increased utilisation of residual raw materials from wild catches (fishmeal, oil, silage) and reduction of floor fish and unsold products in the Industry/VAP segment.

Level of fishmeal, oil and silage produced from residual raw material have increased by 39% from 2019 to 2020.

The increase is mainly cause of the new vessel Kongsfjord producing silage and optimalization of oil and meal production. Volumes in 2021 and 2022 will not have such significant increase, increase will mainly be in optimizing meal, oil & silage production. Level of meal, oil and ensilage production was in 2020 40% of available residual raw material.

In Industry and VAP segment reducing food waste is to among other sub projects reduce level of floor fish (products falling on the floor in the production) and unsold products (products expired or ingredients not used in products).

It has been challenging finding a good reporting solution for Industry/VAP facilities in reporting floor fish and unsold product total for the Group. We therefor do not have sufficient data from 2019 to compare with. Level of floor fish and unsold products was in 2020 around 412 000 kg total in the group. All facilities are working according the action plan to reduce floor fish and unsold products.

Other Food waste reduction projects

Project 50/50-5 Plastic

About 5 kg of CO2e are emitted for 1 kilogram of plastic – 2 kg resulting from the production of the plastic and 3 kg of CO2 are emitted when the plastic is burned after use. For some types of plastic, the number may be 4.5 – and for others 5.5. Source: Norwegian Climate Foundation

Lerøy’s programme, as a Group, is reduce non-recyclable plastic consumption by 50%, including reduction in total plastic consumption. All 60 companies in the Group will contribute to achieving the goal and have established sub-projects with goals for each company.

Each company has established a detailed action plan so that the Group can achieve the target in total by 2024. Cooperation, reporting and following up takes place at three segment levels: Farming, Wild catch and VAP, Sales & Distribution. Cooperation at segment level allows us to utilise ideas and actions across similar operations within the Group, improving our contribution towards achieving the main goals.

Over the past year, the Group has carried out a thorough evaluation of the sub-projects to assess the actual effect and impact of the measures taken – and to ensure that they are making a difference!

Our understanding is that all plastic is recyclable as long as it is possible to collect and sort in the right fractions. Therefore, "non" recyclable plastic is interpreted as plastic in wrong place.

We aim to reduce non-recyclable plastic consumption by 50%, including reduction in total plastic consumption. For Farming we measure amount of feed tubes and ropes purchased, for wild catch, Industry and VAP we measure amount of vacuum film, plastic bag sheet and single use hygienic equipment purchased.

Summarized; to reduce plastic purchased as a result of the different sub projects. Less plastic used equals less plastic in wrong place or less kg of plastic per kg products produced.

For 2020 the group used 1 931 731 kg of plastic within the identified areas. No sufficient data from 2019.

Other plastic consumption reduction projects