Non-compliance with environmental laws and regulations

The company had no violations of the regulations which resulted in fines in this area.

Water usage

The worlds dependency on clean freshwater have never been greater. With an increasing global population, increased temperatures due to increased Co2 emissions and increased pollution, it has become even more important to govern our water sources in a sustainable manner.

LSG take this responsibility seriously and strive to protect and safeguard the freshwater sources we draw water from. We have devised strict protocols and procedures to make sure that we never draw on more water than we are allowed to.

We do this based on extensive risk analysis and preventive actions. This also protects local habitats and wildlife in addition to reduce our impact on local water levels. We also continue our effort to switch all flow through systems to RAS. In 2020 we closed down 5 flow through systems and replaced them with one facility using RAS technology. This change was the biggest contributor to reaching our goal of a 5 % reduction in fresh water use. In total we reduced our usage of freshwater with 5,1 % in 2020.

In our operations, and mainly the Smolt operations, there have been identified risks which may have a negative impact on our operations. Long term drought has the highest consequences for our operations and may cause severe impacts on both fish welfare and our financial situation. Long term drought which will deplete our water reserves in magazines is however deemed unlikely since access to clean high quality freshwater in Norway is good.

In 2020 LSG sourced 97,8 % of its fresh water from surface water sources, and 1,3 % from Municipality sources. In total we used 0,27 m3 freshwater per kg fish produced in the group. The farming segment used 14,09 m3 per kg fish produced, while our slaughterhouses used 0,00063 m3 freshwater per kg fish produced, and our VAP segment used 0,0065 m3.

RAS

The RAS (Recirculating Aquaculture Systems) technology allows Lerøy Seafood Group to produce fish with up to 99% reduction in water use compared to conventional flow-through systems. The Group started to use RAS-technology already in 2005. In 2021, approximately 80% of all salmon smolt in Lerøy Seafood Group will be reared with this technology.

Waste water

We continue our work with water treatment and discharge. Most of our processing factories, new and old, are equipped with fat separators and UV light treatment. In some factories, where it’s necessary, we also have chemical treatment of waste water in addition to mechanical treatment.

New technology and proximity to a biogas facility in Sweden have made it possible for one of our factory to send wastewater for treatment there, and at the same time recover biogas from the waste water. This has resulted in eliminating treatment on site which is beneficial for all parties.

Our operations consummation of freshwater is not significant. We have therefore defined our discharge of wastewater to be the same as our intake of freshwater.

Waste handling and Sorting

Improving our handling and sorting of waste is a continuous priority for LSG. Sorting waste for reuse, recycling and recovery will greatly impact our environment through reduction of unwanted, hazardous and non-biodegradable waste in the environment .

We have implemented strict sorting regimes in all our locations and strive, in collaboration with our waste handling companies, to make sure that all our waste is handled correctly by us and the recipient of the waste. In this the different waste handling companies and local governments are the main contributor and drivers to make the big changes. Without involvement, dedication and investments from them, it will be difficult to see a significant change in share of waste being recycled, reused and recovered.

Many have argued that the incentives to sort and handle waste correctly is somewhat mute, because large quantities of waste is sent to landfills or to undisclosed destinations for incineration. Because of this we are committed to continue our work in different forums like the UN Global Compact initiative to do what we can to push for change.

Our goal for 2020 was to increase the share by 10 % compared to 2019.

We experienced however a decline with 4,73 % % compared to last year. This may be explained by several factors. The 7 % overall reduction of non-organic waste we generated in 2020 is one of them. Another contributing factor is that our waste fractions are more or less constant. Meaning that without change in how our waste is handled by waste handling companies, our share of waste which is recycled, reused and recovered will also be more or less constant. We can partly solve this with higher involvement with private companies which can reuse our waste to other purposes.

The share of hazardous waste in LSG is about 2% of the total amount of waste we generate. Some of our factories still use fluorescent lights, so by changing them to LED lights we can reduce this even further. In addition, the electrifying of our feeding stations will also reduce our hazardous waste by eliminating the use of oils and lubricants for our generators.

Electricity

The Group has established different revolutionary measures in order to reduce environmental impact; from obtaining power from land, hybrid fleets, floating solar cells, to working boats.

Wherever it is possible, the Group seeks to use electricity sourced from land-based powerlines instead of electricity from generators at each production site.

Power from land:

Power from land usually makes good overal economic sense.

Power from land results in:

The further development of power from land should entail a degree of overcapacity, thus enabling any future electrified boats to be recharged.

More than 65% of our sites now run on power from land – a figure that will increase in the coming years. In 2020, there is a plan to replace fossil-fuelled generators at 19 production sites. We will then have 85% of the Group`s sites on renewable electricity.

The various measures require technological development and a high level of expertise, and in many ways, they represent a breakthrough in the industry.

Where the infrastructure is insufficient for land-based electricity, Lerøy Seafood Group is developing hybrid solutions that allow for up to 30% more efficient use of fossil fuels at each site. The Group has hybrid solutions with batteries at two production sites.

Organic non-edible materials

Organic non-edible materials from all our activities represent about 26% of our total volume produced. We categorize these from 1-3. Of the total volume of organic non-edible materials, 0,1% is category 35,8% is category 2, and 59,1% category 3.

The Group strives to increase the share for human consumption, and aims to increase this by 50% by 2024. Projects across the Group have been ongoing since 2018.

We have e.g. invested in a harvest boat which will significantly increase fish welfare and volumes for harvest from our farming operations. This will reduce the volume in Category 2 significantly. In addition, several projects in our VAP, Sales and Distribution segment will contribute to the reduction of food waste and increase the level of raw materials for human consumption.

Recycling

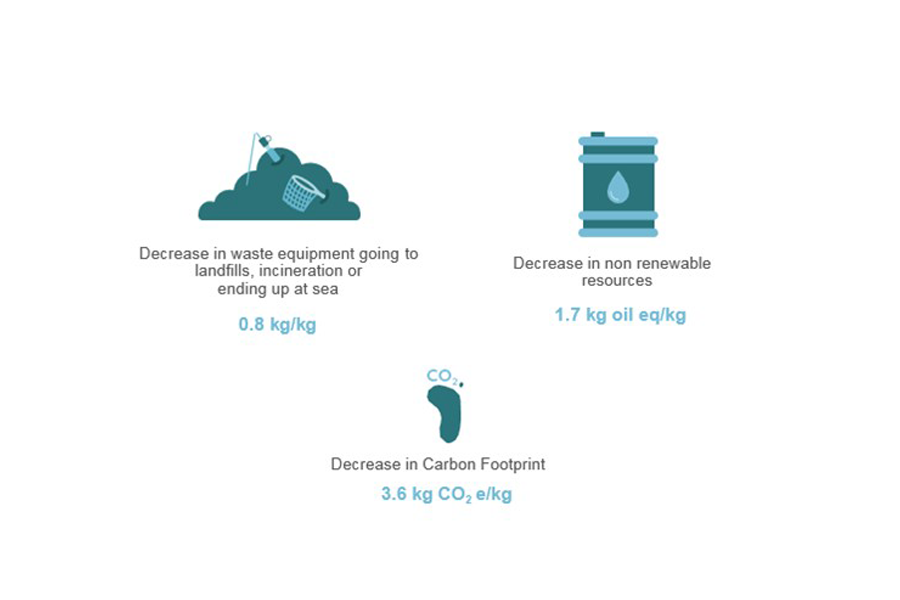

The Group is actively involved in the process of recovering plastic waste from the oceans through different programes, in order to protect marine wildlife. One of the activities is recycling our fish farming nets, yarn and old trawls.

Another activity is: “ Only on loan”. This is a project in which Lerøy Seafood works together with waste and recycling company Norsk Recycling to ensure that the packaging for products packed in aluminium trays is returned for recycling after use. Such packaging is therefore only “on loan”. Waste is a resource that is not properly utilised, and we aim to do something about this. We also focus on using the correct packaging and the correct size of products in order to avoid waste.

Effects of recycling of fish farming nets, yarn and old trawls

Use of Organic sludge from Smolt production

Since 2013, when the juvenile production facility Belsvik opened, we have sent our organic sludge to a biogas production facility. The use of Organic sludge as biogas is sustainable, but we found that the long transportation of sludge with high content of water was less sustainable.

Investment in a drying facility on location was therefore recently decided and from 2023 we will be able to deliver dried sludge to the agriculture industry.

The Sludge will be used as a soil improvement material and fertilizer. Our other two major smolt production sites in Laksefjord and Kjærelva is already drying their sludge on site for the agriculture industry.

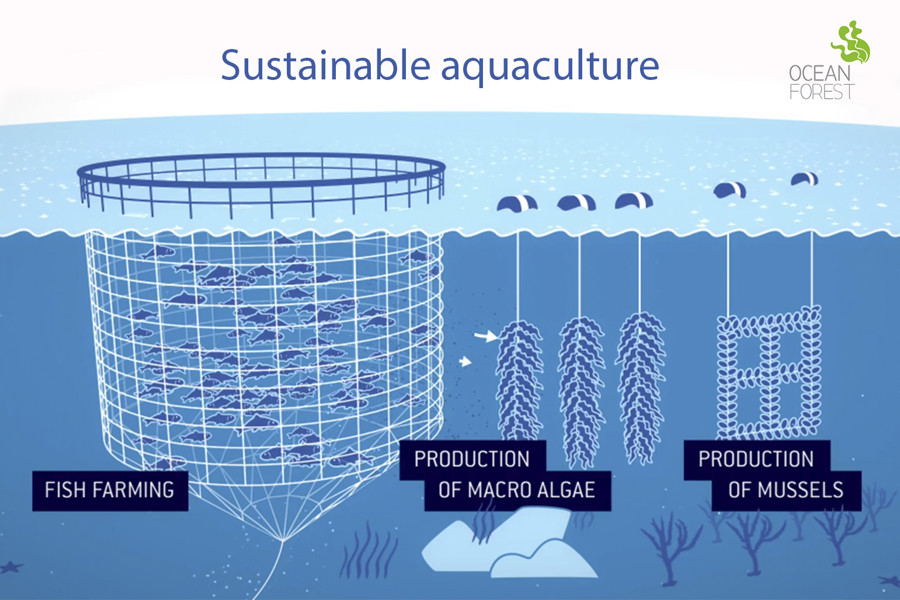

Sugar kelp

The Group is also producing sugar kelp, which is another example of recycling. When we produce sugar kelp we use the nutritions from fish farming to produce sugar kelp and blue mussels.